Airtel IoT Smart EV Solution helps leading OEM extend battery life and vehicle health

-

September 10, 2024

-

5 min read

The electric vehicle (EV) industry is witnessing an unprecedented surge, driven by a global push toward sustainable transportation. However, as EV demand soars, the need for enhanced battery performance has become critical. To achieve this, manufacturers need to overcome certain challenges, including delivering batteries that are high-performing, safe and cost-effective.

Did you know?

The Indian EV market is expected to skyrocket to US $ 113.99 billion by 2029 and is poised to become the largest EV market by 2030.

Source: https://www.ibef.org/industry/electric-vehicle

At the heart of this ecosystem is the Battery Management System (BMS). This critical component oversees battery health, optimises charging, and prevents potential hazards, making a robust BMS essential for maximising battery life and enhancing vehicle performance. However, when a leading vehicle OEM began facing issues with its legacy BMS, it turned to Airtel for help.

The Challenge

Legacy BMS led to battery safety and performance issues

The OEM was struggling with ensuring the reliability and safety of its batteries while maintaining high performance. The legacy BMS they relied on was outdated, unable to keep pace with the evolving demands of modern electric vehicles. Due to this, the OEM faced many critical issues, such as:

-

No Configurability:

The rigid BMS could not adapt to different battery configurations, limiting the OEM’s ability to optimize performance across various vehicle models.

-

Impossible to Repair or Maintain:

The lack of diagnostic capabilities meant that any issues with the BMS could not be easily identified or resolved, leading to extended downtimes and higher replacement costs.

-

Life-Threatening Batteries:

The risk of thermal runaways and other safety hazards posed serious threats to both the users and the reputation of the OEM.

-

No Diagnostics for Bug Fixing:

Without proper diagnostics, the OEM was unable to troubleshoot and fix issues, exacerbating the problem and leading to a higher rate of battery failures.

Additionally, the OEM admitted to struggling with the complexity of managing multiple suppliers. Different vendors for different BMS components led to a fragmented ecosystem, which caused inefficiencies in quality control and other interoperability challenges. With no unified structure in place, there was a lack of clear accountability when it came to any problem with the BMS. These further delayed resolutions and added to the OEM’s operational challenges. The consequences were severe: an alarming increase in warranty claims, safety concerns due to battery failures, and a lack of visibility into the health and performance of the batteries. These lead to not only financial losses but also the risk of damaged reputation.

The Solution

Simplified operations, superior results with Airtel Smart BMS

Recognizing the need for a comprehensive solution, the OEM decided to adopt Airtel’s IoT Smart EV Monitoring and Management Solution. The end-to-end solution included a state-of-the-art BMS designed to address the exact challenges the OEM was facing. Key benefits included:

-

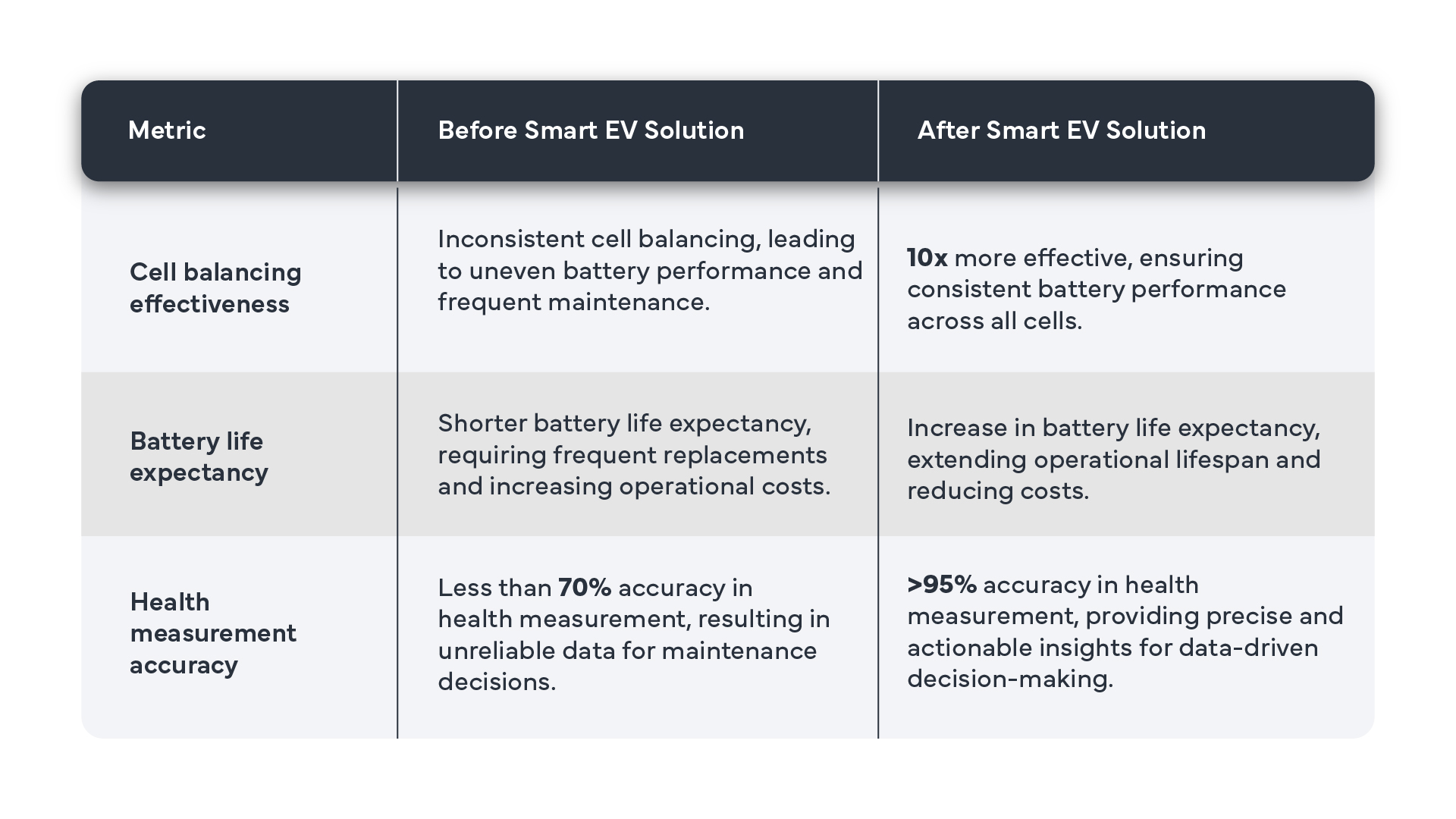

Best-in-Class Cell Balancing:

Superior cell balancing ensured optimal performance and safety, crucial for extending the life and reliability of the batteries.

-

Production Configuration Menu:

The Smart BMS supported a wide range of on-the-go configurations. The OEM was able to adapt the BMS to various battery types and vehicle models, providing the flexibility needed to meet diverse customer needs.

-

Unique Battery Health Monitor (BHM):

The BHM feature enabled continuous monitoring of battery behaviour from the very first cycle, allowing early detection of potential issues and facilitating timely interventions.

-

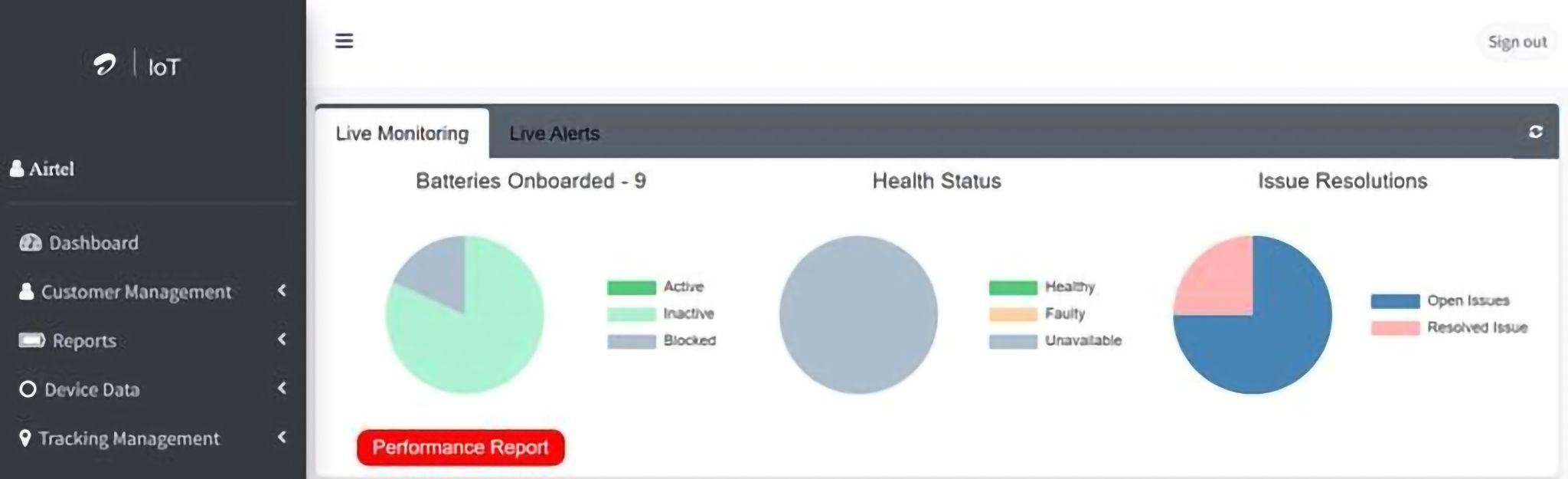

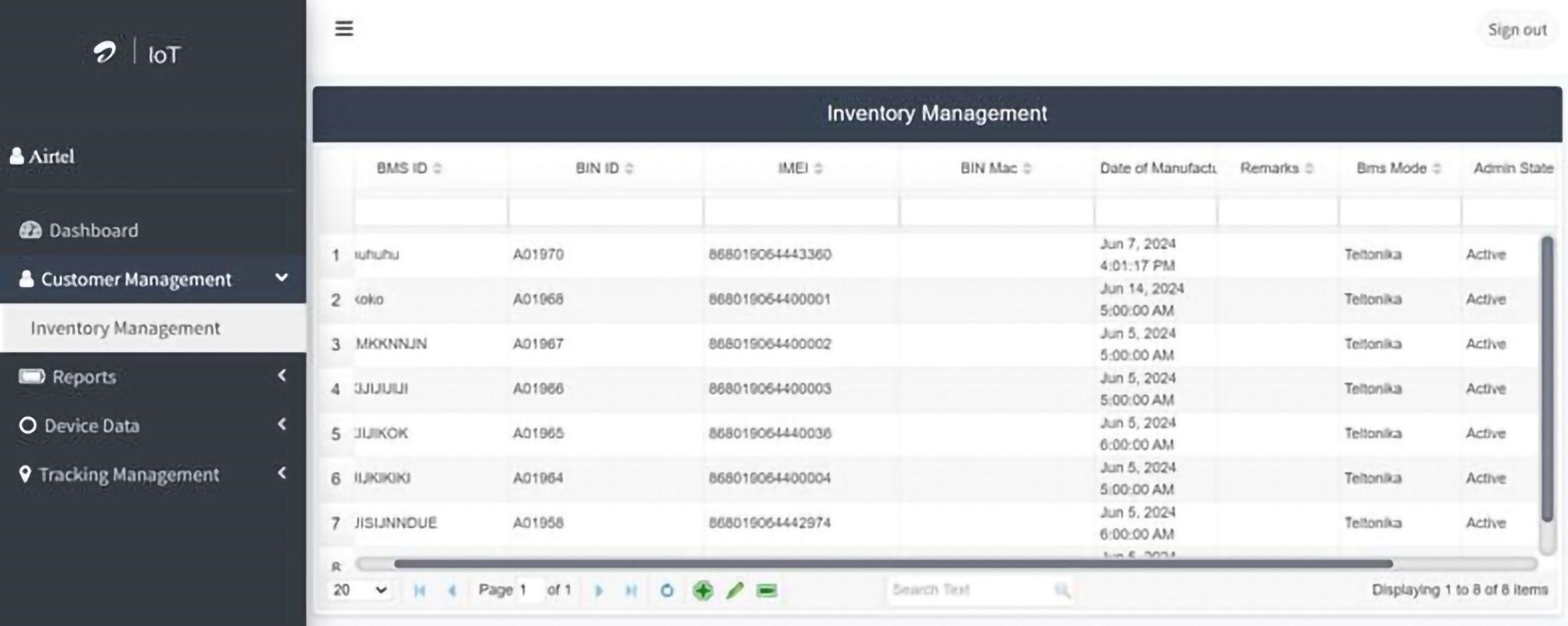

Online Dashboard and User App:

The real-time monitoring capabilities provided by the online dashboard and user app offered comprehensive insights into the performance of each individual battery, helping in quicker identification and resolution of problems.

-

Automated Safety Alerts:

Proactively ensuring safety, the BMS was equipped with AIS 156 ++ protection features, significantly reducing the risk of safety hazards.

But Airtel’s solution went beyond just addressing the technical issues. By providing a single, integrated platform, Airtel simplified the OEM’s operations. No longer did the OEM have to juggle multiple suppliers; instead, Airtel became the one-stop shop for all their battery and vehicle management needs. This not only improved operational efficiency but also enhanced control over the entire battery lifecycle.

The Impact

Major gains in battery performance and operational efficiency

Implementing Airtel’s EV Solution with Smart BMS brought about a significant transformation in the OEM’s operations, both technically and from a business perspective.

Technical Impact

Business Impact

Cost Reduction:

Improved battery performance and longevity contributed to a decrease in operational costs, since the need for frequent battery replacements and maintenance interventions was significantly reduced.

Scalability:

The scalable design of Airtel’s solution allowed the OEM to efficiently manage and expand their fleet without compromising on performance or data accuracy.

Improved Reputation:

By leveraging advanced monitoring and data analytics, the OEM could offer more reliable EVs, enhancing customer satisfaction and positioning themselves as a leader in innovation and quality within the market.

Conclusion

Airtel’s EV solution with Smart BMS has proven to be a game-changer for the OEM, addressing critical challenges and driving significant improvements in battery performance, safety, and overall vehicle efficiency. By offering a comprehensive, integrated solution, Airtel not only resolved the immediate issues but also set the OEM on a path to sustained success in the rapidly evolving EV market.

Share

Share