Top Trends in Manufacturing Supported by Managed SD-WAN

-

April 10, 2024

-

3 min read

In today’s rapidly evolving digital landscape, businesses continually seek innovative solutions to streamline operations, enhance connectivity, and improve overall efficiency. Smart factories are reshaping the manufacturing landscape, leveraging advanced technologies to optimize production processes, enhance efficiency, and drive innovation. Managed SD-WAN solutions are key technologies driving this transformation. As we navigate 2024, several trends are emerging, highlighting the need for Managed SD-WAN services in the manufacturing businesses. Let’s explore the top trends in Managed SD-WAN services:

-

Edge Computing for Real-time Insights

Smart factories generate vast amounts of data from sensors, machines, and production lines. Edge computing, integrated with SD-WAN solutions, enables manufacturers to process and analyse this data locally, in real-time, at the network edge. By harnessing edge computing capabilities, manufacturers can derive actionable insights, optimize production processes, and minimize latency, enhancing overall operational efficiency.

-

Secure Connectivity for Industrial IoT (IIoT)

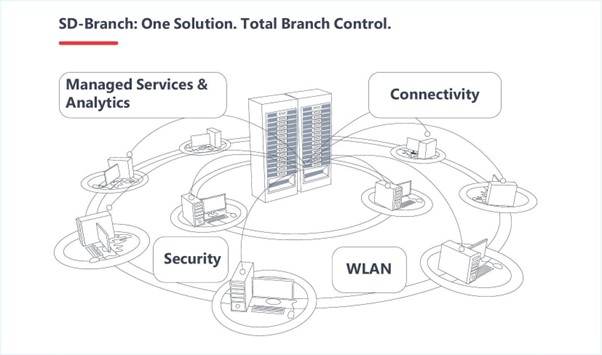

The proliferation of Industrial Internet of Things (IIoT) devices in smart factories necessitates robust and secure connectivity solutions. Managed SD-WAN services are integrated with advanced security features tailored for industrial environments. Security features include encryption, access controls, and intrusion detection systems to safeguard against cyber threats and ensure the integrity of IIoT data and operations.

-

Network Orchestration and Automation

As smart factory networks become more complex, there’s a growing demand for network orchestration and automation. SD-WAN solutions with intelligent orchestration capabilities enable manufacturers to dynamically manage their network, prioritize traffic, and adapt to changing production demands. Automation streamlines network provisioning, configuration, and maintenance tasks, reducing manual intervention and enhancing operational agility.

-

Multi-site Connectivity and Collaboration

Manufacturers with distributed operations require seamless connectivity and collaboration across multiple sites and geographies. SD-WAN solutions offer centralized management and control, facilitating secure and reliable communication between smart factory locations and value chains. By optimizing multi-site connectivity, manufacturers can improve resource utilization, synchronize production processes, and accelerate time-to-market.

-

Predictive Maintenance and Remote Monitoring

Proactive maintenance is critical for minimizing production downtime and maximizing equipment uptime in smart factories. SD-WAN solutions integrated with predictive analytics enable manufacturers to predict and fix potential network issues thereby enabling them to monitor equipment health in real time, detect anomalies, and predict potential failures even before they occur. By facilitating real-time data sharing, SD-WAN allows maintenance teams to remotely perform diagnostics, troubleshoot issues, and initiate repairs promptly, optimizing asset performance and reducing operational costs.

-

Hybrid Cloud Adoption

Smart factories are increasingly adopting hybrid cloud architectures to leverage cloud computing’s scalability and flexibility while maintaining control over sensitive data and applications. SD-WAN solutions facilitate seamless integration with hybrid cloud environments, enabling manufacturers to optimize workload placement, ensure data privacy, and improve access to cloud-based services and applications.

In conclusion, Managed SD-WAN solutions are instrumental in transforming manufacturing units into smart factories. Airtel Managed SD-WAN provides end-to-end network visibility through a single-pane-of-glass to ensure seamless connectivity of the total manufacturing stack, including IIoT and OT (Operational Technology) devices.

By embracing these top trends and leveraging advanced networking solutions, manufacturers can unlock new opportunities and gain competitiveness in Industry 4.0. These trends will streamline operations and pave the way for sustainable growth and success in the manufacturing sector.

Share

Share